NEW MANUSCRIPT ON COMBINED EPD&HS TECHNOLOGY FOR MINERALOGICAL RESEARCH IS OUT FOR PUBLISHING IN

- 23 янв. 2018 г.

- 2 мин. чтения

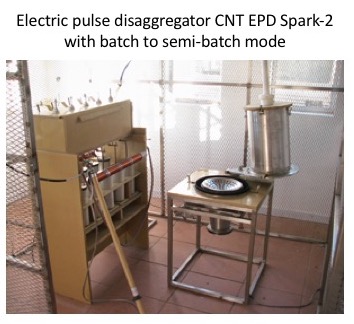

Laboratory studies of ore formation and quantitative process mineralogy should include studying all constituents of samples, including accessory minerals on a single grain level. The described technology combines two complementary methods - electric pulse disaggregation (EPD) and our patented hydroseparation (HS). Such combined EPD&HS technology is used as unique solution for mineralogical research of bedrock, ore and processed products. It also includes the following stages of the sample processing and research:

1) mineralogical and geochemical analyses of the primary sample;

2) EPD of the sample (by means of the CNT EPD Spark-2 device);

3) wet screening of EPD products;

4) obtaining heavy mineral concentrates by hydroseparation (by CNT HS-11) from each size fraction;

5) selection of characteristic grains of useful (indicator) minerals from the coarse fractions of the heavy mineral HS-concentrates;

6) monolayer polished sections from all heavy mineral HS-concentrates;

7) mineralogical in-situ investigations of monolayer polished sections of the heavy mineral HS-concentrates and selected characteristic grains by quantitative mineralogical methods;

8) the synthesis and compilation of all information related to research tasks. Combined EPD&HS technology is now used successfully in various research centers and universities around the World resulting in over 300 publications: see www.cnt-mp.com.

The most popular applications of the combined EPD&HS technology are:

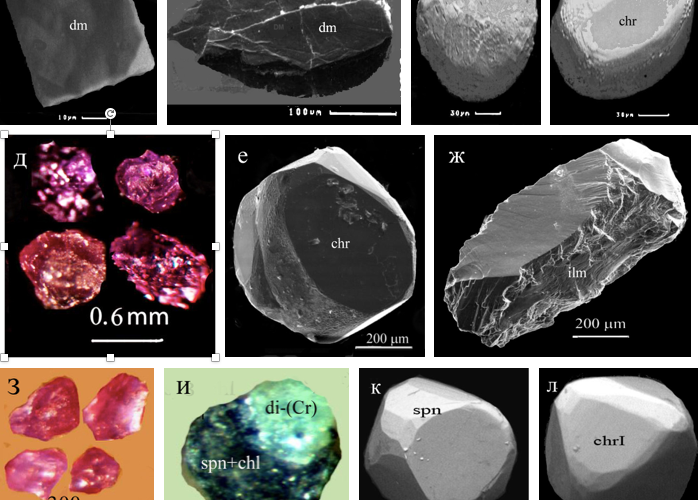

I) mineralogical investigation of ores of precious metal deposits, especially gold and platinum group elements (PGE);

II) discovery of new precious metal minerals;

III) study of potentially diamondiferous rocks;

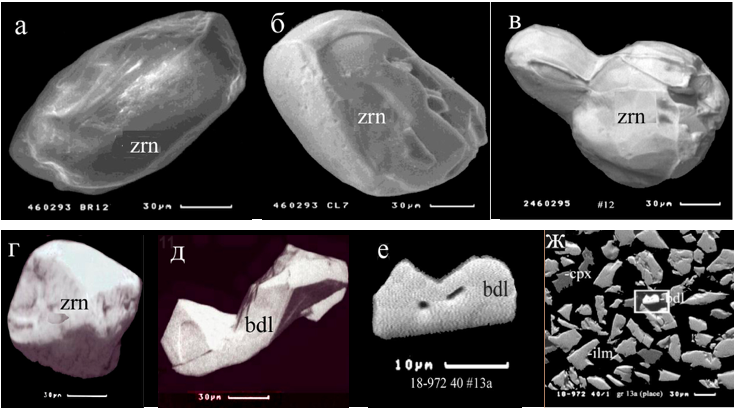

IV) extraction of fine grained particles for geochronology (zircon, baddeleyite, apatite, rutile, Os-minerals and others);

V) use of EPD for paleontology.

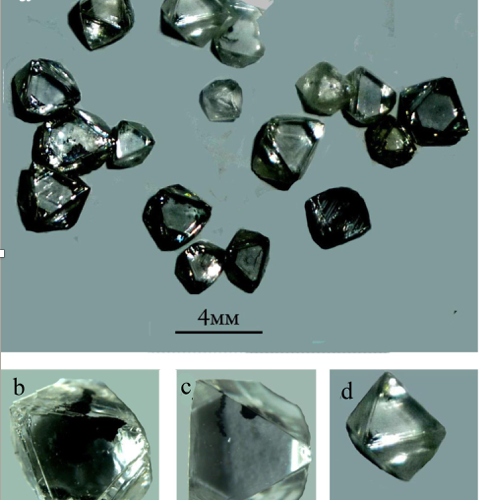

VI) EPD recovery of undamaged pristine crystals of gemstones and diamonds

Our new manuscript will describe some examples of combined EPD&HS technology application in geology, mineralogy, applied mineralogy and mineral processing for several rocks and ores are briefly described:

I) Ores of precious metal deposits

- Pt-Au-Pd-ores of the “Platinova Reef” deposit of Skaergaard massif, Greenland;

- Ag-Au-Pd-Pt-ores of the Bushveld Complex (chromitites of UG2, LG6, M1/2, Merensky Reef), South Africa; -- Au-Ag-ores from the Veladero deposit, Argentina; Au-Ag-ores of the Berezovsky deposit, the Urals;

- Ag-Au-Pt-Pd-mineralization of carbonatites from Kovdor Massif, Kola Peninsula and Loolekop deposit, Phalaborwa Massif, South Africa;

II) Eight new platinum-group minerals which include six being discovered by the authors of the manuscript;

III) Diamondiferous lamproite diatreme, Karelia, Kostomuksha district;

IV) Zircons of garnet amphibolites of the Kamchatka Cape Peninsula, Eastern Kamchatka; Os-placer and host-rock mineralization of the Ust-Belsky massif, Koryak highlands;

V) Microfossils from sedimentary rocks, North Dakota, USA.

Have great 2018 and enjoy reading our new paper on most efficient technology for process mineralogy and unique solution for mineralogical research of bedrock, ore and processed products!

Комментарии